Most puzzle players probably wondered how the puzzles were actually made.

From the first image design step to the final packaging steps, every step goes through many complicated processes. The choice of cardboard, the way it is cut, and how the surface is treated can all affect how the puzzle feels and how long it lasts.

Pieces that look simple actually have a whole complex process behind them.

Now we will show you, step by step, how these exquisite puzzles are made.

From Idea to Design

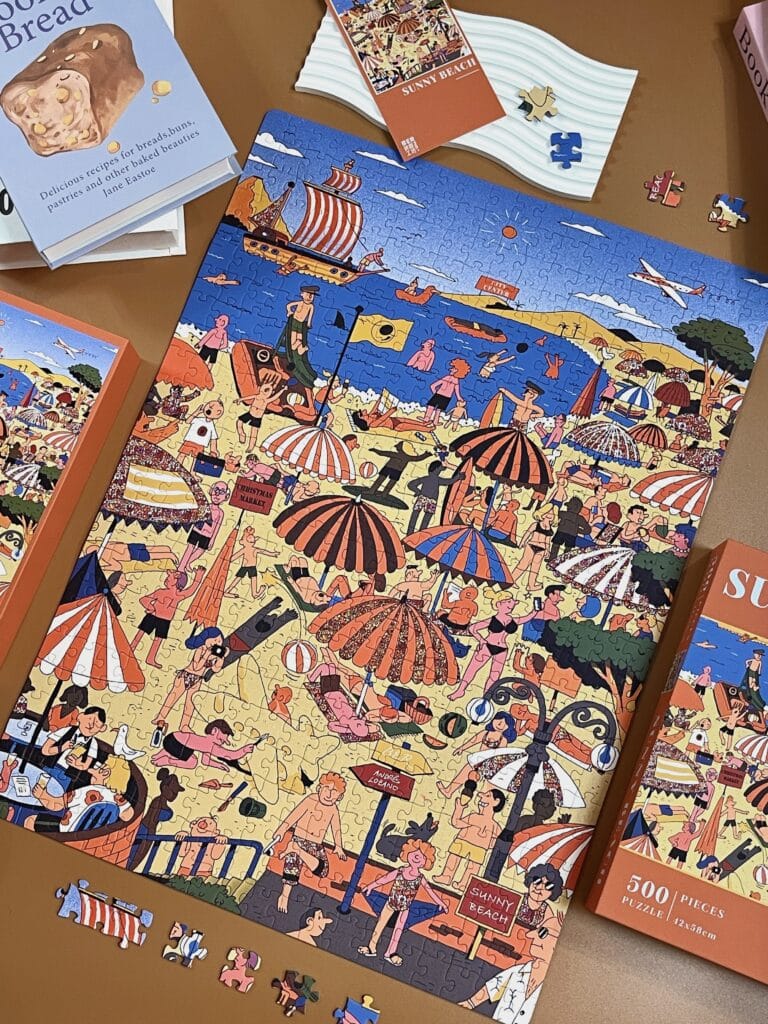

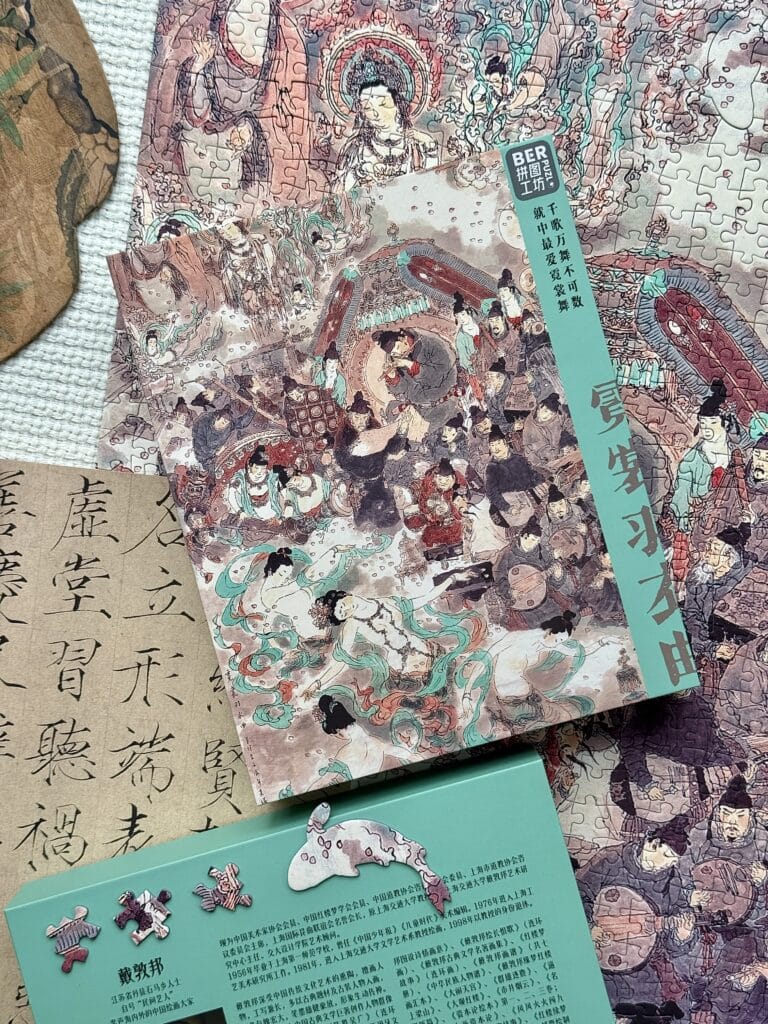

The very first step in creating a jigsaw puzzle is choosing the artwork—a decision that essentially defines the soul of the puzzle. At Ber, we collaborate with exceptionally talented artists, selecting beautiful existing works or commissioning new creations around specific themes. Popular puzzles such as Great Sage Equal to Heaven, Christmas Blessings, Azure Coast, Sunny Beach, and Canaletto Blick all originated from renowned artists.

Once the artwork is finalized, the design and proofing stage begins. Using professional editing software, the image is first converted from RGB to CMYK, then matched with an ICC color profile to ensure accurate reproduction. Bleed margins and layout impositions are also prepared. The finalized file is then sent to the printer for test proofs. If the sample colors appear off, further adjustments are made until the proof delivers the fullest and most faithful rendition of the original artwork.

Printing the artwork

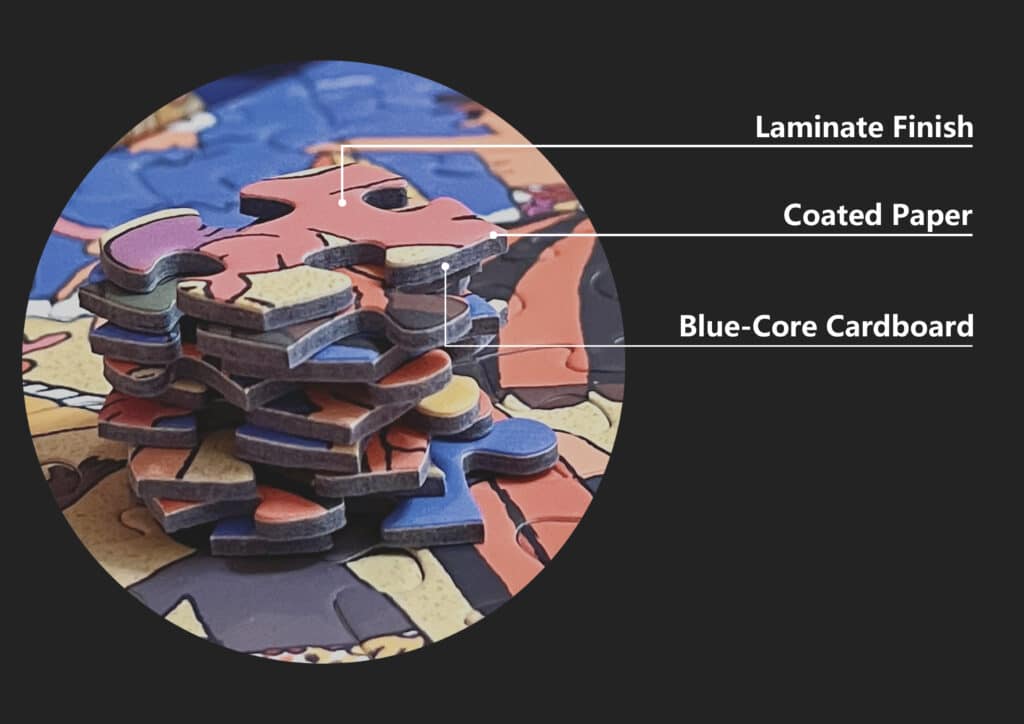

After the artwork has been selected and the color proofing completed, the process moves into full-scale production. For large production runs, puzzles are typically printed using four-color offset printing. The imagery is transferred onto high-quality coated paper sheets, which are then prepared for the next critical step—the lamination process.

Surface finishing

In order to prevent puzzle wear and improve the appearance and texture of the puzzle, the surface process will continue to be refined after the printing is completed, this step is mainly for two purposes:

- Protection: Protects the puzzle from wear, moisture, and fingerprints, increasing its durability and longevity.

- Aesthetics: Enhance the look and feel of the puzzles, adding the right atmosphere and texture to the puzzles with different patterns and themes.

In this step, there are mainly two optional processes, one is UV-cured coatings. and aqueous coatings, and the other is BOPP/PET film coating. aqueous coatings dry quickly and have low costs; UV coating is harder and brighter, but the resulting puzzle is prone to reflection and can only be used in combination with specific patterns. Meanwhile, the BOPP/PET film coating is divided into many different effects, such as matte film, tactile film, fine glitter film, etc. Regardless of the style of laminating, it will be harder, thicker, and more scratch resistant than the first kind of coatings, which will significantly increase the production cost of the puzzle.

Since most puzzle enthusiasts do not like puzzles that are prone to reflection, so we generally choose More textured matte coatings, and the most commonly used one is “Matte Velvet Laminated Finish”, which is also the most popular technique among players.

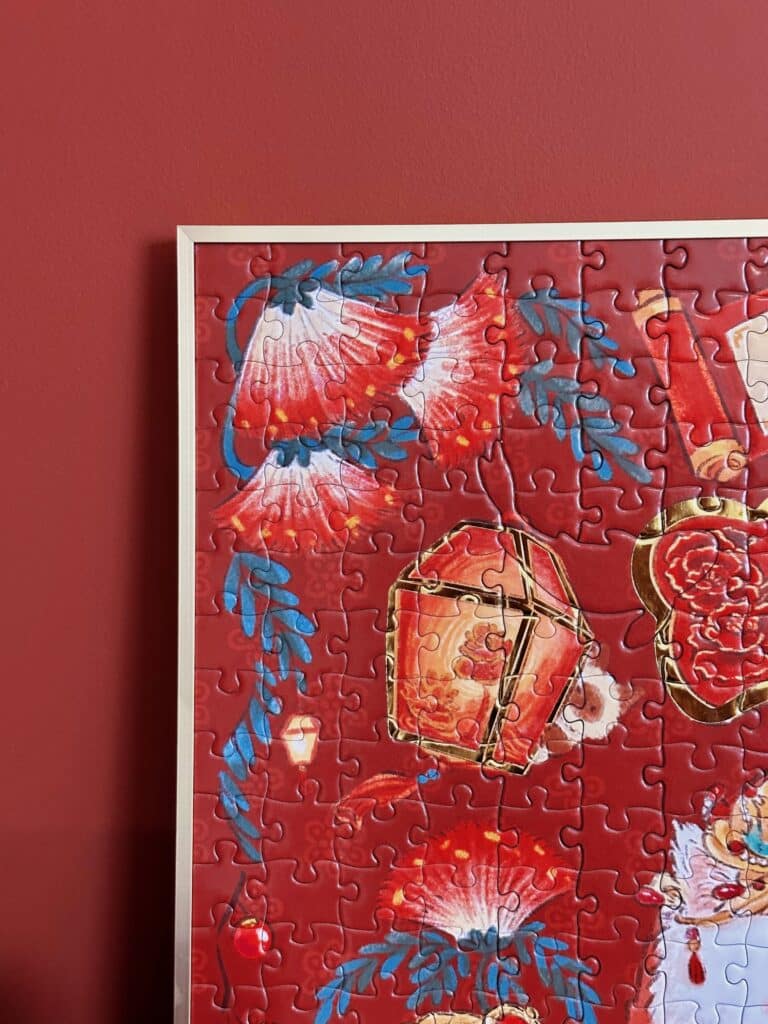

But a quality brand is not limited to these monotonous crafts. Sometimes, in order to present the puzzle with a more stunning effect and make players feel a more vivid atmosphere, we also mix and design different crafts into a new craft with a unique effect. For example, our “Everlasting Harmony” uses a combination of glossy and matte films, as well as hot stamping technology, so that the puzzle can not only avoid reflection, but also keep the surface gloss of the puzzle from overshadowing the focal effect of hot stamping, while maintaining the smooth touch of the oil surface. This craft is our unique characteristic craft.

Mounting

The next step is the board mounting process. In the first few steps, we have produced the printed product images with film coating.

Next, we need to use glue to mount these images onto the selected core board, and then use a pressure roller to exhaust and compact them to ensure full contact and remove bubbles.

After compression, we also need to dry them (precise control of moisture and curl is required for puzzle making to maintain paper flatness), and finally trim the edges.

Making the die & die-cutting

Once the printing and mounting process is fully complete, the puzzle sheets are ready for die-cutting.

Every puzzle brand has its own signature piece shapes, and Ber is no exception. Our puzzle pieces are meticulously designed in-house, with all standard pieces being original creations. Some puzzles even include a surprise custom-shaped “Koi” piece, a distinctive feature that makes our puzzles truly one-of-a-kind in the market.

Creating truly unique puzzle pieces requires custom die molds. Once the molds are crafted, they are used in precision cutting machines to cut the puzzle sheets. While the overall die-cutting process is similar across the industry, the quality of the machinery makes a significant difference—affecting the smoothness of the piece edges and the fit between pieces.

To ensure the highest standard of quality, Ber invests in state-of-the-art cutting machines, allowing us to produce puzzle pieces with the most elegant shapes and the most satisfying tactile feel.

Breaking apart pieces, inspection and quality control

After the entire puzzle making process is completed, we can start the packaging process.

The first step in packaging is using a slicing machine to automatically break up a whole piece of puzzle, then collect scattered puzzle pieces and put them into plastic packaging bags.

In this step, the staff will inspect whether the puzzle pieces are cut cleanly, whether there is peeling or scratching on the surface, etc. After the inspection is completed, the bag can be sealed.

Final packaging

Finally, just one step remains before a perfect puzzle is ready. The sealed puzzle pieces, along with accompanying extras—typically postcards, fridge magnets, reference guides, and other small gifts—are carefully placed into beautifully printed gift boxes and then wrapped in a protective plastic outer sleeve.

To ensure the ultimate puzzle experience, our gift boxes are thoughtfully designed using sturdy, high-quality board, providing a premium tactile feel. This makes unboxing a truly satisfying experience, perfect as a personal treat or as a special holiday gift for family and friends.

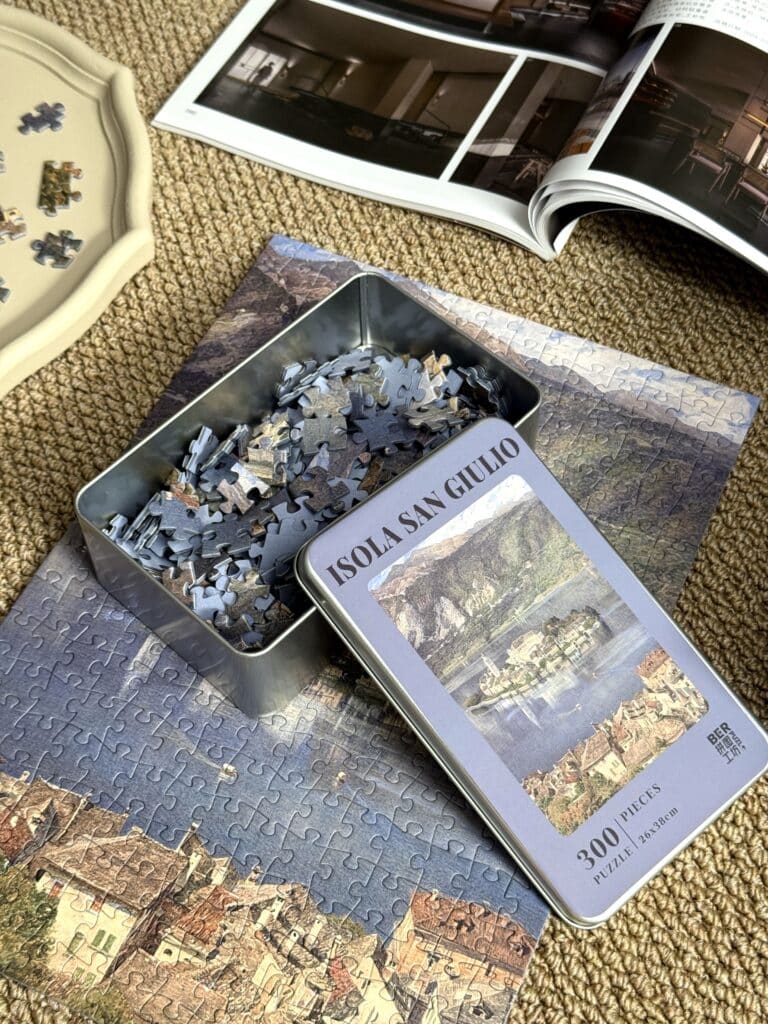

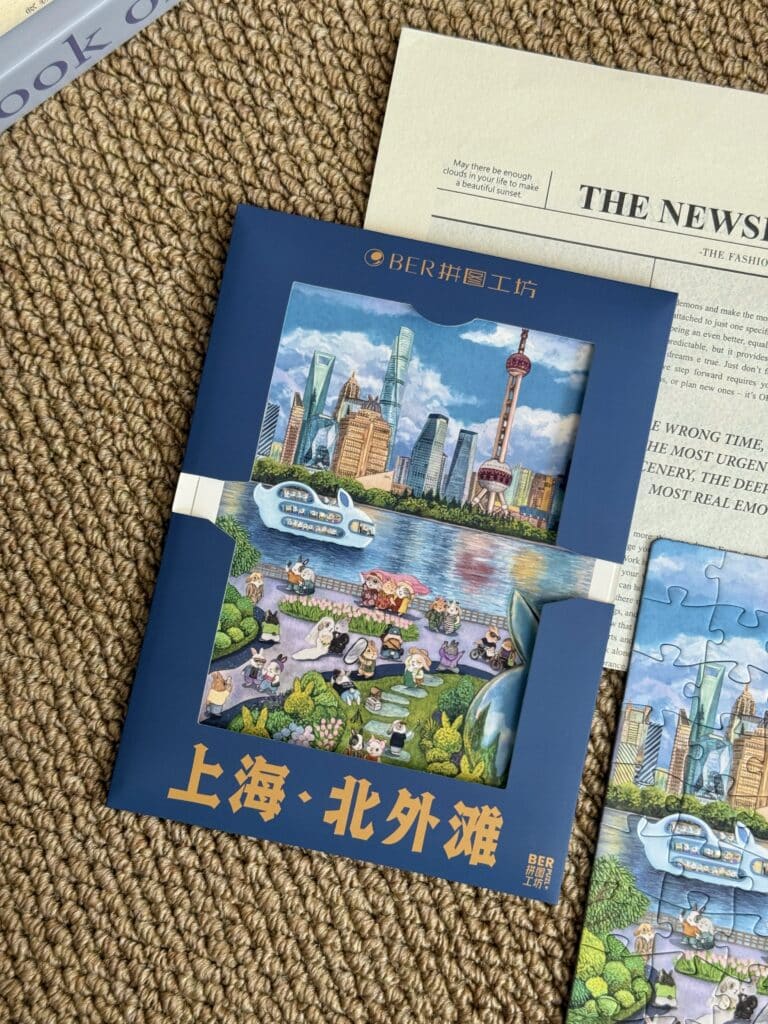

Ber puzzles come in three main packaging styles: gift box packaging, commonly used for 500- or 1,000-piece puzzles; candy-style box packaging, typically for 300-piece puzzles; and postcard-style packaging, used for pre-assembled postcard-sized puzzles. Beyond these, we also offer more playful options such as blind-box editions, including the “Chinese New Year Puzzle Advent Calendar” and “Good Fortune”.

![The Bustling and Hustling of Nanjing, With Image Downloads in All Sizes [CN:南都繁会图]](https://berpuzzle.com/wp-content/uploads/2025/10/南都繁會圖_01-768x576.jpg)